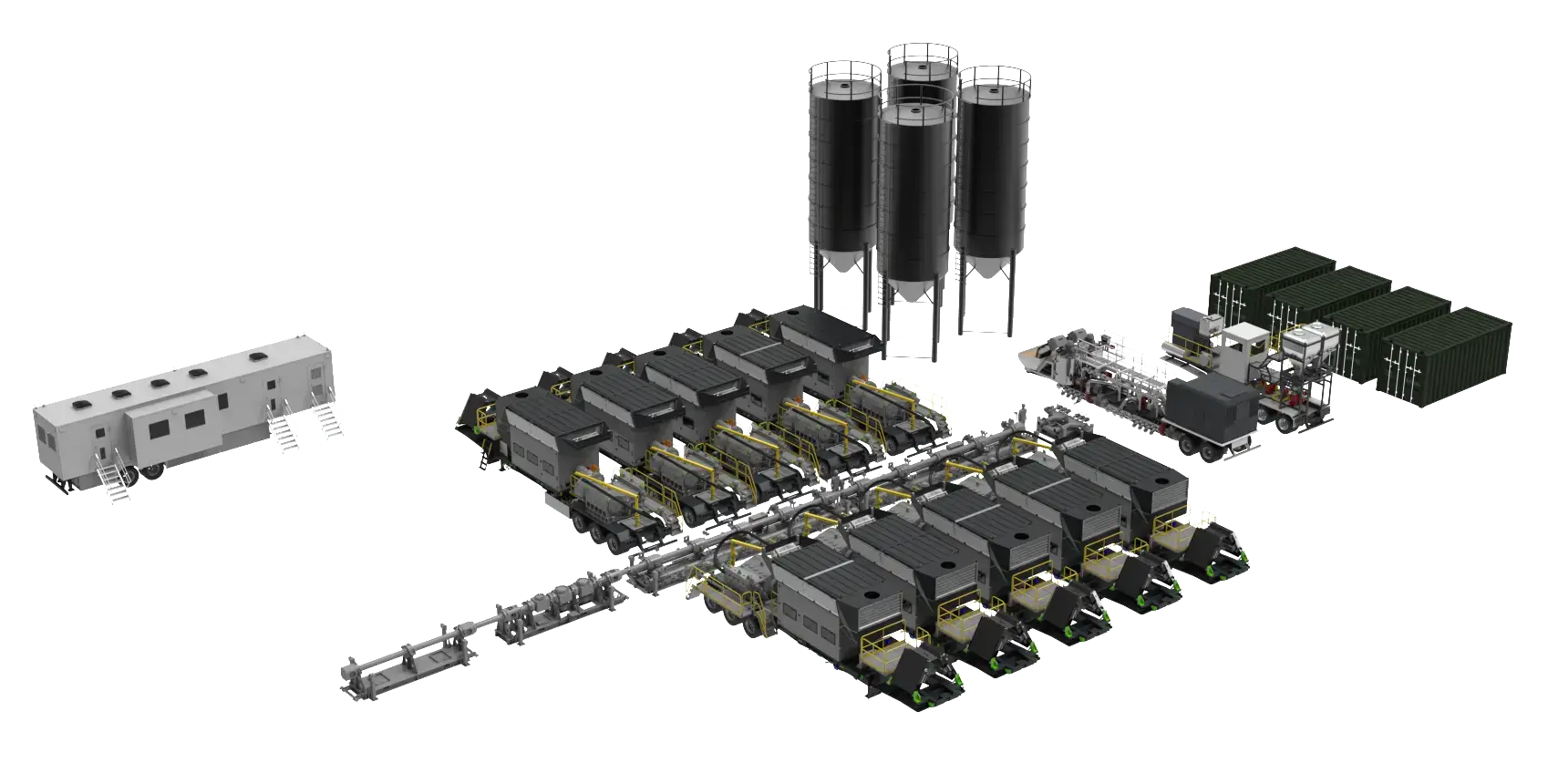

Fracturing pump

- Fracturing Pump (Diesel or Gas Engine / Gas Turbine)

- Deliverable power from 2250 to 5000 HHP

- Pumping capacity up to 14 BPM at 11500 PSI continuous

- Driven by diesel, bi-fuel, gas, or electric power

- Customization of motor-transmission-pump assembly

- Polymer Additive Unit

- Hydration Unit

- Dry Polymer Mixer

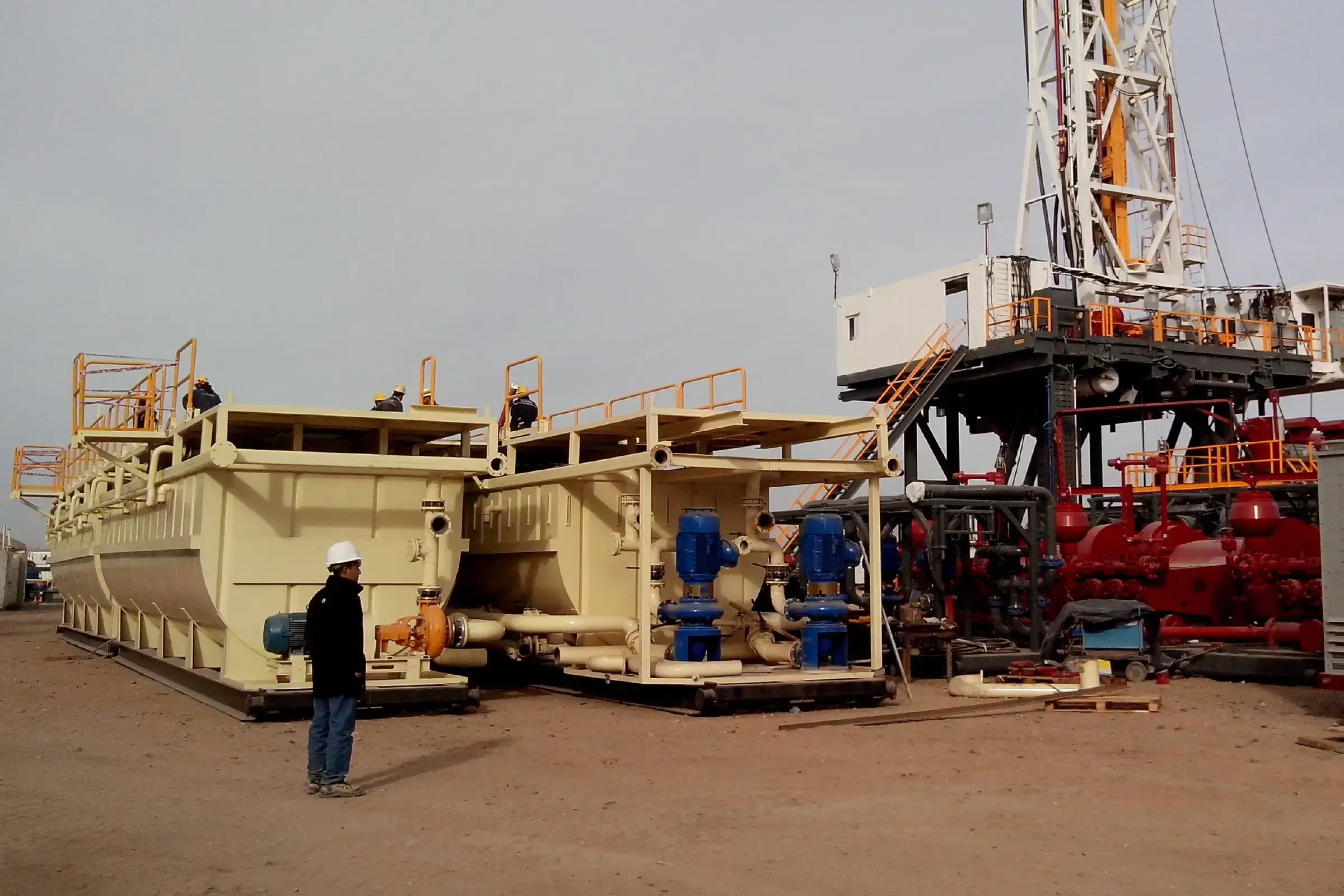

Blender

- Configuration of 60, 120, and 160 BPM

- Driven by diesel or electric power

- Sand handling of up to 20000 lb/min

- Automated operation

Large bore

- 7-1/16" Line

- Configurable quantity of modules and outlets

- Rigid/Flex hose piping

- Instrumentation skid

Data van

- Fracturing fleet control and monitoring

- Acquisition and storage of operation data

- Integration of fracturing pumps, blenders, and complementary units

- Satellite and Wi-Fi connectivity

- Management and analysis of large volumes of information

Silos

Hydration Unit

Flaring Mitigation

We develop solutions for flaring mitigation using Rich Burn technology engines that allow the use of flared gas without prior treatment, for electricity generation, cryptocurrency mining, data center services, or grid contribution.

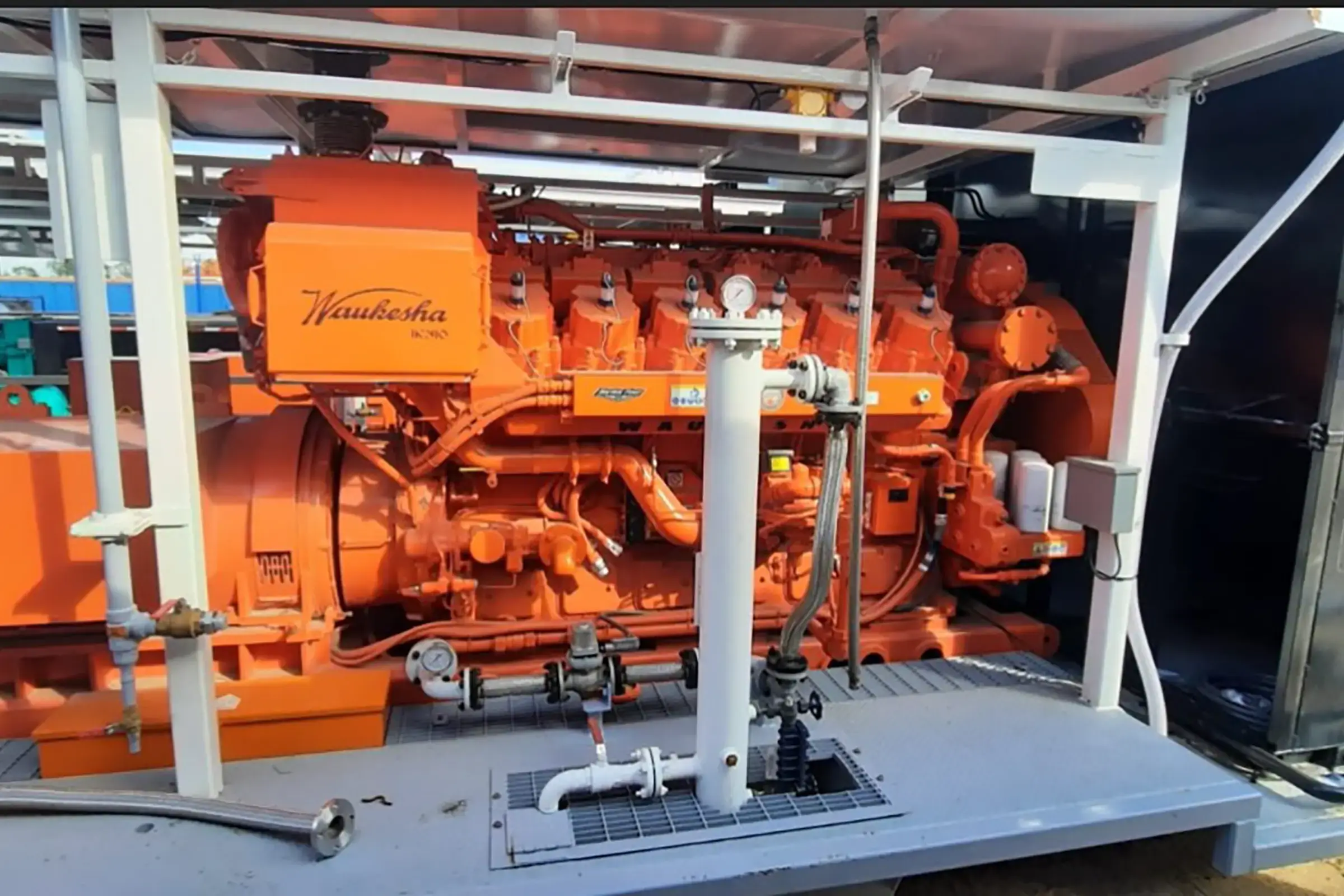

Electric Generation for Drilling

We design and package on-site electric generation equipment using well gas with Rich Burn technology, which allows for a transient load response similar to diesel engines without the need for battery backup.

Electrification

We develop comprehensive turnkey mobile solutions to adjust network supply parameters in Drilling or Well Service operations, maximizing fuel savings and consequently reducing equivalent carbon dioxide emissions.

Renewable Energies

We adapt our manufacturing capabilities for the renewable energy industry. Our lifting capacity of up to 80 tons and experience within the Oil & Gas industry allowed us to diversify our role, becoming service providers for the assembly of nacelles and hubs in the wind industry. Additionally, we promote the development of wave energy through technological collaboration with CONICET.

Control systems

We excel in the design and manufacturing of specialized equipment for the oil & gas industry, with a particular focus on the integration of advanced sensors, automated controls of complex processes and adaptability of communication protocols.